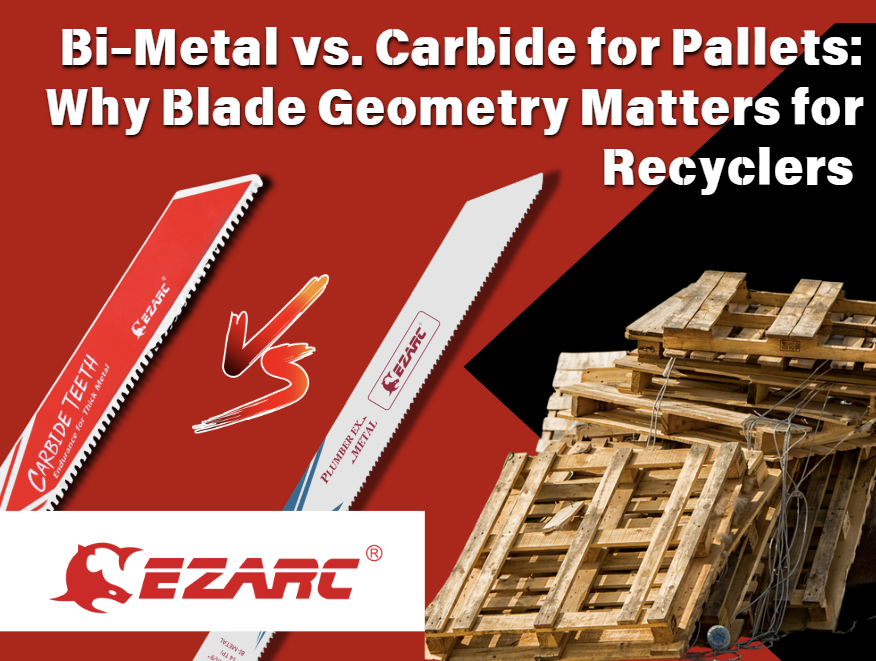

For pallet recyclers, reclaimers, and high-volume dismantlers, blade choice directly impacts productivity, cost, and wood recovery rates. In 2026, the debate isn’t about whether to use a saw—it’s about bi-metal vs. carbide blades, and more importantly, why blade geometry matters when using a reciprocating saw blade for pallets .

This guide breaks down the real-world differences between bi-metal and carbide blades, explains how tooth geometry affects performance, and helps recyclers choose the right reciprocating saw blade for pallets for their operation.

Why Blade Choice Matters in Pallet Recycling (reciprocating saw blade for pallets)

Pallet recycling is brutal on tools. Nails, staples, hardened fasteners, and mixed hardwoods all punish blades quickly. The wrong blade can:

- Slow down dismantling lines

- Increase blade replacement costs

- Damage usable pallet boards

- Increase operator fatigue

That’s why professionals rely on a purpose-built sawzall blade for pallets rather than standard demolition blades.

Understanding Blade Geometry for Pallet Dismantling

Blade geometry refers to how a blade is engineered—its tooth shape, spacing, gullet depth, and overall flexibility. These factors determine how efficiently a sawzall blade for pallets cuts through nail-embedded wood.

Key Geometry Factors

- Tooth Pitch (TPI): Medium tooth counts (6–9 TPI) balance speed and control

- Tooth Shape: Optimized profiles reduce nail hang-ups

- Blade Flexibility: Prevents snapping when cutting hardened fasteners

- Kerf Width: Thinner kerfs preserve more wood fiber

Well-designed geometry allows a sawzall blade for pallets to cut nails cleanly instead of tearing through boards.

Bi-Metal Blades: The Workhorse Option

Bi-metal blades remain the most popular choice for pallet recyclers worldwide.

Advantages of Bi-Metal Blades

- Flexible steel body resists snapping

- Hardened teeth handle nail-embedded wood

- Lower upfront cost per blade

- Ideal for mixed pallet loads

Cost Efficiency.

reciprocating saw blade for pallets

delivers excellent performance for everyday dismantling and is especially attractive for recyclers managing operating costs.

Bi-metal blades are affordable, and during sales or bulk buys, they can drop to around $1 per blade, making them extremely cost-effective for high-throughput pallet yards. ","contentAlignProduct":"Left","infoProduct":{"id":"gid://shopify/Product/7481653100695","title":"Pallet Dismantling – Bi-Metal, 9 in, 10/14 TPI Reciprocating Saw Blade","currencyCode":"USD","amountMax":"18.95","amountMin":"18.95","price":"18.95","compareAtPrice":null,"imagesUrl":"https://cdn.shopify.com/s/files/1/0575/4975/0423/files/R922PR_Detail_01_IMG_816817dd-d32d-4c24-bf40-355ad505c60d.jpg?v=1702878880&width=600","urlStore":"/products/ezarc-reciprocating-saw-blades-set-9-inch-bi-metal-with-cobalt-nail-embedded-wood-pallet-repair-multi-purpose-demolition-blades-for-reciprocating-sawzall-saws-sabre-saws-10-14tpi-10-pack","altImage":"10/14tpi,9 in. Bi-Metal Reciprocating Saw Blade Set For Pallet Dismantling - EZARC Tools"},"colorDiscount":{"hue":356,"saturation":0.74,"brightness":1},"colorTitle":{"hue":213,"brightness":0.83,"saturation":1},"colorPrice":{"hue":0,"saturation":1,"brightness":0},"cssContent":"","activeDecimals":false,"decimalsPrice":2,"isRemoveBranding":true}

A quality bi-metal

reciprocating saw blade for pallets

delivers excellent performance for everyday dismantling and is especially attractive for recyclers managing operating costs.

Bi-metal blades are affordable, and during sales or bulk buys, they can drop to around $1 per blade, making them extremely cost-effective for high-throughput pallet yards.

Carbide Blades: Built for Extreme Durability

Carbide-tipped blades represent the premium tier for pallet dismantling.

Advantages of Carbide Blades

- Exceptional resistance to nail wear

- Long lifespan in high-volume operations

- Consistent cutting performance over time

- Reduced blade change downtime

A carbide sawzall blade for pallets may cost more initially, but its durability makes it ideal for recyclers cutting thousands of pallets per month.

Bi-Metal vs. Carbide: Head-to-Head Comparison

| Feature | Bi-Metal Blades | Carbide Blades |

| Upfront Cost | Low | Higher |

| Blade Life | Moderate | Very Long |

| Flexibility | High | Moderate |

| Nail Resistance | Good | Excellent |

| Best Use Case | General recycling | Heavy-duty, high volume |

Both options can serve as an effective reciprocating sawzall for pallets when matched to the right workload.

Why Geometry Matters More Than Material Alone

Many recyclers focus only on blade material, but geometry often matters more. A poorly designed carbide blade can underperform compared to a well-engineered bi-metal sawzall blade for pallets .

Optimized geometry ensures:

- Faster nail separation

- Cleaner board recovery

- Less vibration and heat buildup

- Reduced operator fatigue

Material determines longevity—but geometry determines efficiency.

Choosing the Right Blade for Your Recycling Operation

Ask these questions before selecting your sawzall blade for pallets :

- How many pallets do you dismantle daily?

- Are pallets hardwood, softwood, or mixed?

- Is downtime from blade changes costly?

- Do you prioritize lower cost or longer lifespan?

Best Practices

- Use bi-metal blades for general recycling and budget control

- Use carbide blades for continuous, high-volume dismantling

- Keep separate blades dedicated only as a reciprocating saw blade for pallets

Common Mistakes Recyclers Make

- Using demolition blades not designed for pallets

- Ignoring tooth geometry and TPI

- Running dull blades too long

- Mixing pallet work with metal-only cutting

Each mistake reduces the effectiveness of your sawzall blade for pallets and increases overall costs.

Final Thoughts: Blade Geometry Is the Competitive Edge in 2026

In pallet recycling, efficiency wins. Whether you choose bi-metal or carbide, the real performance advantage comes from blade geometry engineered specifically for pallet dismantling. The right sawzall blade for pallets increases throughput, protects usable lumber, and lowers long-term costs.

For recyclers looking to stay competitive in 2026 and beyond, understanding blade design isn’t optional—it’s essential.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

댓글 남기기

이 사이트는 hCaptcha에 의해 보호되며, hCaptcha의 개인 정보 보호 정책 과 서비스 약관 이 적용됩니다.