When it comes to raw power and versatility, few tools can match the reciprocating saw, better known by its popular name, the Sawzall. But one of the most common questions DIYers and professionals alike ask is: “How thick of metal can you cut with a Sawzall?”

The short answer? It depends on your blade, specifically, on the metal Sawzall blade you choose.

In this guide, we’ll break down how thick of metal you can realistically cut, what factors limit performance, and which blades (like EZARC’s premium carbide options) make the difference between a struggle and a clean, controlled cut.

- 1. Understanding How a Sawzall Cuts Metal

- 2. How Thick of Metal Can You Cut?

- 3. Factors That Affect Cutting Thickness

- 4. Types of Metal Sawzall Blades

- 5. How to Know If a Blade Is Designed for Metal

- 6. EZARC’s Recommendation for Thick Metal

- 7. Other Blade Options to Explore

- 8. Tips for Cutting Thick Metal Efficiently

- 9. Why EZARC Metal Sawzall Blades Stand Out

- 10. Final Thoughts

Understanding How a Sawzall Cuts Metal

A Sawzall isn’t just about raw power, it’s about the right combination of blade material, TPI (teeth per inch), and design.

A Sawzall can cut through a surprising range of metals: thin sheet metal, pipes, rebar, cast iron, even high-strength alloys. But to do so efficiently, you need a blade designed for the task, a proper metal Sawzall blade that’s built to handle heat, friction, and hard materials without dulling or snapping.

Using the wrong blade, like one meant for wood or demolition, can overheat, chip, or even warp the teeth. That’s why knowing your blade’s limits is just as important as knowing your saw’s power.

How Thick of Metal Can You Cut?

🔹 Light Metal (Up to 1/8 inch / 3 mm)

For thin metal sheets, HVAC ducts, or steel flashing, a standard bi-metal Sawzall blade with 18–24 TPI is ideal. The fine tooth pattern prevents snagging and ensures a smooth, controlled cut.

🔹 Medium-Thickness Metal (1/8 inch – 3/8 inch / 3–10 mm)

For items like conduit, angle iron, or steel tubing, step down slightly in TPI, something around 10–14 TPI works best. You’ll get a balance between speed and precision.

🔹 Thick Metal and Heavy Steel (Up to ½ inch / 12 mm or more)

When you’re tackling thick cast iron, stainless, or alloy steel, you need a carbide Sawzall blade. These feature tungsten carbide teeth that can stay sharp up to 20× longer than standard bi-metal blades.

With this type of metal Sawzall blade, cutting through ½-inch steel plate or 4-inch cast-iron pipe becomes entirely possible with the right technique and saw power.

Factors That Affect Cutting Thickness

Even the best metal Sawzall blade performs differently depending on a few variables:

1. Blade TPI (Teeth Per Inch)

- Higher TPI = slower, smoother cut (for thin metal)

- Lower TPI = faster, rougher cut (for thick metal)

Most metal cutting reciprocating saw blades range between 8 and 24 TPI, depending on thickness.

2. Blade Material

- Bi-metal blades (steel + HSS teeth): good for medium-duty cutting

- Carbide Sawzall blades: premium option for thick, tough metals

- High-speed steel blades: cheaper, but dull quickly if used to cut metal

When you’re working with rebar, cast iron, or hardened steel, carbide teeth are the only choice that will last.

3. Saw Power and Speed

A powerful reciprocating saw (corded or high-amp cordless) with variable speed helps maintain consistent control. Let the blade do the work, forcing it only shortens its life.

4. Cutting Technique

Use slow, steady strokes for thick metal. Lubrication or cooling spray can extend blade life. For deep cuts, make sure you’re using the full blade length to distribute wear evenly.

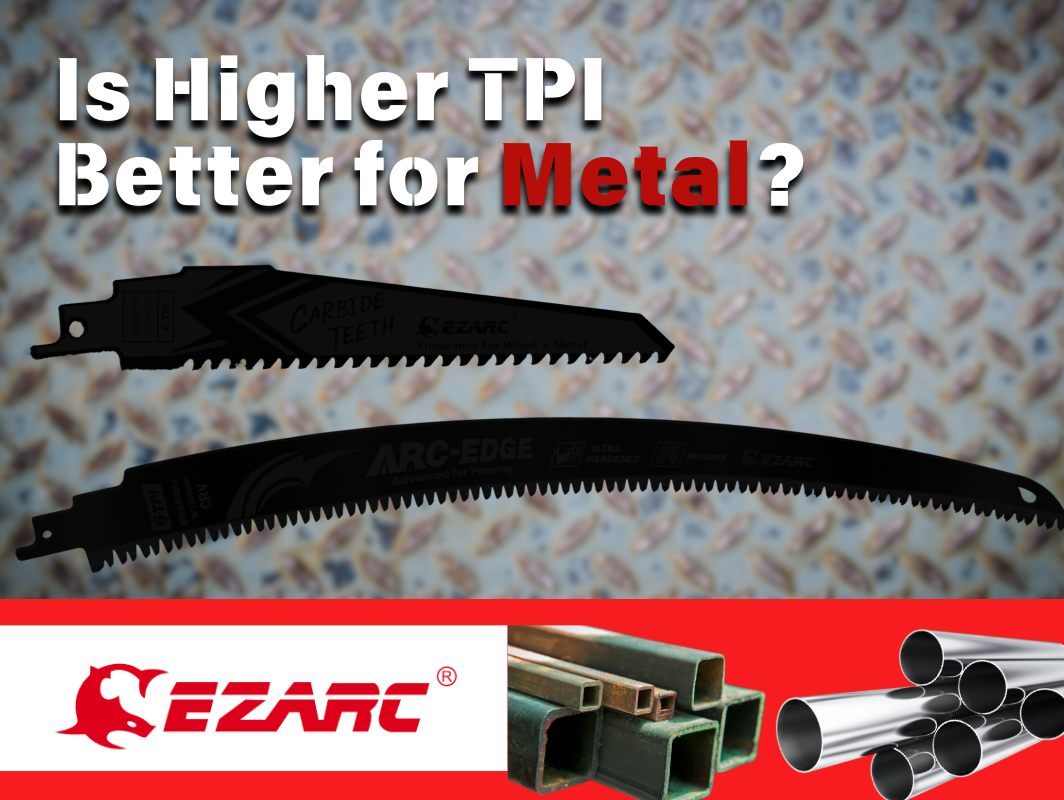

Types of Metal Sawzall Blades

To get the most out of your tool, you should know the main types of metal Sawzall blades:

| Blade Type | Ideal Use | TPI Range | Material | Example |

| Thin-Metal Blade | HVAC ducts, sheet metal | 18–24 | Bi-Metal | EZARC Bi-Metal 18 TPI |

| General Metal Blade | Pipes, tubing, mild steel | 10–14 | Bi-Metal | EZARC 10 TPI All-Metal |

| Thick-Metal Blade | Cast iron, alloy steel | 6–8 | Carbide | EZARC 8 TPI Carbide Reciprocating Saw Blade |

When you match blade type to job thickness, you’ll not only cut faster, you’ll extend your blade life dramatically.

How to Know If a Blade Is Designed for Metal

If you’re not sure whether a blade is for metal or not, there are three quick checks:

- Look for labeling such as “metal,” “metal cutting,” or “reciprocating saw blades metal.”

- Check the TPI: Metal blades almost always have > 10 TPI.

- Inspect the teeth: Carbide tips appear chunkier and more rugged; bi-metal blades have finer teeth.

For a deeper dive into how to identify the right blade for your project, see this detailed guide:

Read Our Full EZARC Blade Selection Guide.

EZARC’s Recommendation for Thick Metal

When you’re working with thick steel, cast iron, or high-tensile alloys, you want a blade that doesn’t just survive, it thrives under pressure. That’s where EZARC’s 8 TPI Carbide Metal Sawzall Blade shines.

- Industrial-grade tungsten carbide teeth stay sharp up to 20× longer

- Cuts through cast iron, stainless steel, and alloy up to ½″ thick

- Engineered to minimize vibration for smoother, faster cuts

- Available in 6″ and 9″ lengths for different job sizes

Whether you’re on a demolition site or fabricating metal frames, this metal Sawzall blade is built to deliver power and precision with every stroke.

Other Blade Options to Explore

EZARC offers a wide range of metal cutting reciprocating saw blades, including:

- Bi-metal Sawzall blades for all-purpose metal work

- Carbide Sawzall blades for extreme performance

- Specialty metal cutting Sawzall blades for aluminum, stainless steel, and cast iron

Tips for Cutting Thick Metal Efficiently

- Start slow, finish steady. Let the blade bite into the material, don’t force it.

- Keep blades cool. Heat kills edge retention; use cutting fluid or take short breaks.

- Use proper TPI. The thicker the metal, the fewer teeth per inch you need.

- Support your workpiece. Reduce vibration to protect both the blade and your arms.

- Keep spares ready. Even premium carbide blades wear down eventually, so rotate often.

Why EZARC Metal Sawzall Blades Stand Out

Every metal Sawzall blade from EZARC is engineered with professional-grade precision and durability in mind. The combination of premium carbide teeth, optimized tooth pitch, and vibration-reducing design means you can cut through even the toughest materials with confidence.

Whether you’re a contractor, fabricator, or DIY enthusiast, EZARC blades are built to perform where others quit.

Final Thoughts

So, how thick of metal can you cut with a Sawzall?

With the right metal Sawzall blade, the answer is: as thick as you need to.

From thin aluminum sheets to dense cast iron, pairing your saw with a properly designed blade, like the EZARC 8 TPI Carbide Reciprocating Saw Blade, transforms a tough job into a clean, efficient cut.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。