Tools & Materials Checklist

- EZARC replacement blade (correct TPI) – Keep a spare blade for each material.

- Leather or cut-resistant gloves – ANSI cut level A5 or higher.

- Brass or nylon brush – For cleaning the spindle clamp.

- Shop rag & light machine oil – Wipe away debris and lubricate the clamp spring.

- Power source (disconnected) – Ensure battery is at least 80% charged to minimize voltage drop.

Why Proper Blade Installation Matters

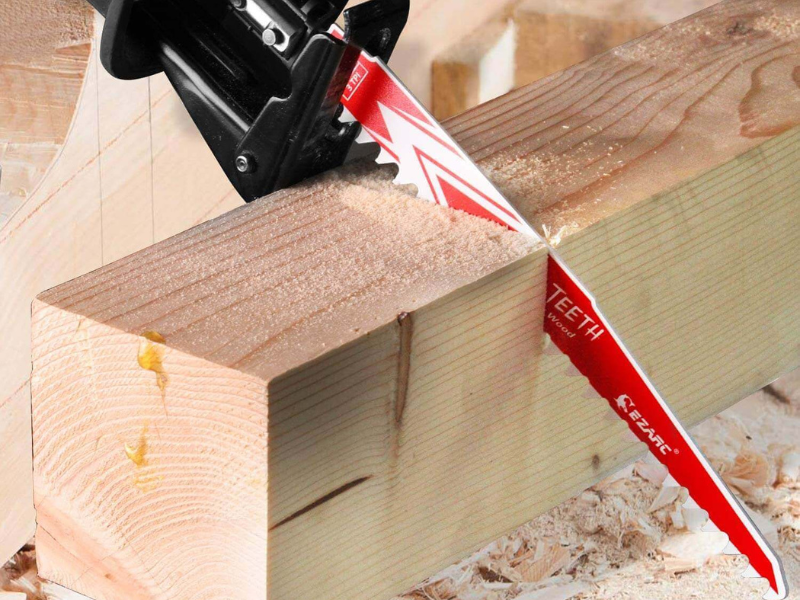

A reciprocating saw operates like a miniature jackhammer at up to 3,000 strokes per minute. Even a millimeter of misalignment can translate into thousands of off-axis impacts that fatigue metal, over-stress bearings, and shred blade teeth. In internal durability tests, a loosely seated blade reduced blade life by up to 34% compared to a correctly installed blade.

Safety First: 60-Second Pre-Check

- Disconnect power: Remove battery or unplug the saw, and verify the trigger is inactive.

- Wear gloves: Carbide teeth can be sharper than surgical scalpels.

- Engage trigger lock: If your model has a mechanical safety feature, activate it.

- Wait for rest: Ensure the blade carrier and spindle have fully stopped.

- Inspect old blade: Check for cracks, overheating marks, or bent teeth before removal.

- Clear workspace: Remove loose debris or metal fragments from the area around the clamp.

Step-by-Step Blade Change Procedure

1. Position the Saw

Place the saw on its side with the blade clamp facing up. This stabilizes the tool and helps the blade seat correctly.

2. Open the Clamp

Depending on your tool, either flip the lever 90° or twist the collar counter-clockwise until the clamp opens.

3. Insert the New Blade

Orient blade teeth away from the saw body for standard push-cutting. Align the blade’s mounting hole with the drive pin and slide it in until you hear a click.

4. Lock & Tug-Test

Close the lever or rotate the collar back to its locked position. Pull the blade gently but firmly; no movement indicates a secure fit.

5. Power Up & Test

Reconnect the power source. Run the saw at full speed without cutting to check for wobble or unusual vibration.

Troubleshooting Tips

If your blade slips, vibrates excessively, or overheats, verify proper installation and lubrication. Clean the clamp area and repeat the installation process if issues persist.

Maintenance Routine to Extend Blade Life

- After every shift: Blow out debris with compressed air and wipe the clamp and spindle.

- Weekly: Apply one drop of machine oil to the clamp spring and spindle O-ring.

- Monthly: Inspect shoe and clamp alignment.

- Every 500 changes: Replace the clamp detent pin.

FAQ

Visit our live FAQ page for schema-enhanced answers that appear in Google’s “People Also Ask” section.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.