When you pick up a reciprocating saw (a “Sawzall”), one of the biggest questions you’ll face is: “Which blade is actually for metal?” Choosing the wrong blade costs time, dulls faster, and can even damage your tool or workpiece. That’s why understanding how to tell a metal Sawzall blade from a wood or multi-purpose blade matters.

In this guide, we’ll break down everything you need to know: what features to look for in a blade meant for metal, how to interpret TPI and materials, and how EZARC makes it simple for you to select the right blade. Then we'll highlight a top-performing EZARC blade built for thick metal. Ready?

Why Identifying a Metal Blade Matters

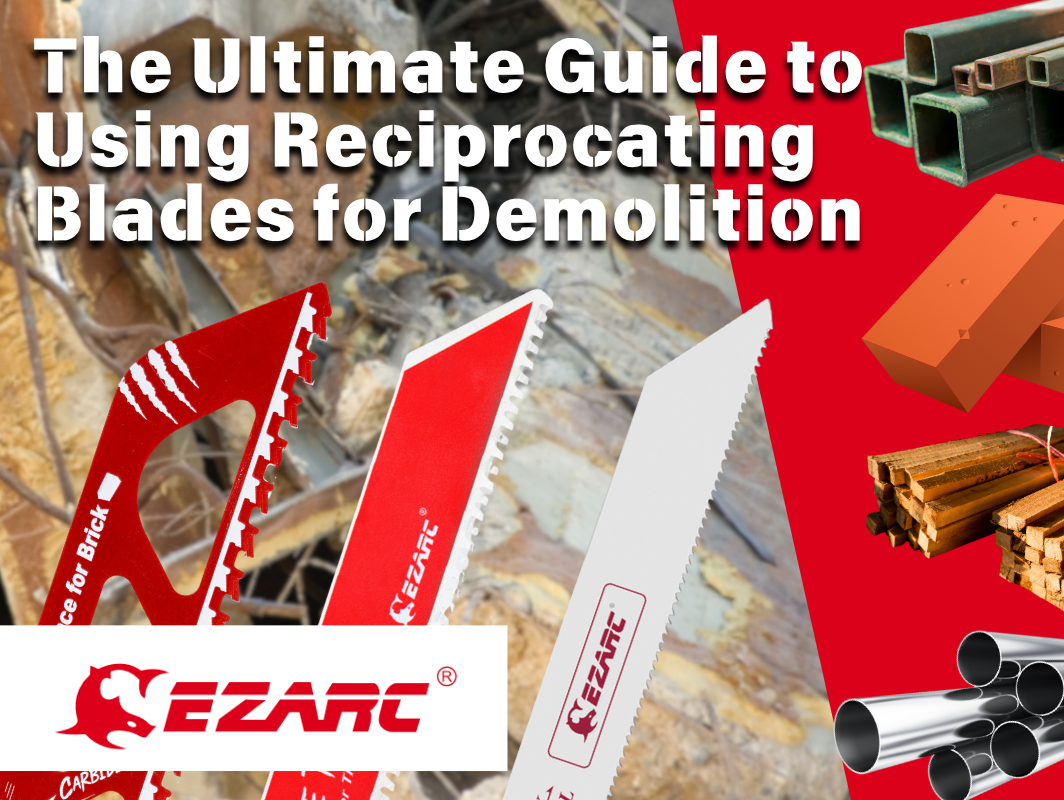

When you’re cutting steel pipes, metal studs, aluminum frames, or even cast iron, a generic wood blade simply doesn’t hold up. It flexes. The teeth wear out quickly. The cut slows down. And you may end up with ragged edges or a ruined blade.

In contrast, a proper metal Sawzall blade is built for the job: designed with the correct tooth count (TPI), body thickness, alloy or carbide tip technology, and designed for metal’s toughness and heat generation.

Using the right blade means faster cuts, fewer blade swaps, less frustration, and better results. EZARC’s own buying guide reinforces this: “TPI (Teeth Per Inch) and tooth design are key. Higher TPI for fine/metal work; lower TPI for wood.”

So how do you tell? Let’s walk through the key indicators.

Key Indicators That a Blade is for Metal

1. Look at the TPI (Teeth-Per-Inch)

One of the fastest indicators. Lower TPI means fewer teeth per inch → faster, rougher cuts (good for wood). Higher TPI means more teeth → smoother, slower cuts through harder materials (good for metal).

- For thin sheet metal, ducting, light gauge steel: look for 14-24+ TPI.

- For thicker metal (pipes, heavier steel): you may see 8-14 TPI in specialist blades.

- If the blade says 6 TPI or less, that’s a red flag for metal work, that’s designed for wood, demolition, or thick, fast cutting wood + nails.

2. Material & tooth tip technology

Metal cutting blades often have upgraded materials:

- Bi-metal blades (flexible steel body + high speed steel teeth) are common for general metal cutting. EZARC lists bi-metal options for metal.

- Carbide tipped blades are top tier: for hardened steel, cast iron, alloys. If the blade says “carbide”, you’re looking at a serious metal blade.

- If you see “wood only” or “nail embedded wood”, it’s not going to perform well in metal.

3. Blade length, width and body thickness

- Metal cutting blades tend to have sturdier bodies (to resist flex and vibration).

- If the blade is very narrow and labeled for wood or pruning, it might not hold up.

- Check the length and shank: for a reciprocating saw you’ll want a universal shank size (often ½″) and length suited to your metal thickness.

4. Labeling and marketing

Check the packaging or description. Look for terms such as:

- “metal cutting Sawzall blades”

- “reciprocating saw blades metal”

- “metal Sawzall blades”

- “best Sawzall blades for metal”

A blade that includes those keywords is a strong indicator. A blade labelled simply “wood” or “multi-purpose” may work, but you may not get the performance you expect.

5. Performance and cost trade-offs

Metal blades cost more (especially carbide tipped). If you inspect the price and it's modest, ask if it’s really built for metal. Also, check reviews: does it hold up to nails, rebar, steel pipe?

How to Choose The Best Metal Sawzall Blade

With your knowledge of metal blades in hand, here’s how to pick the right one.

Step 1: Determine the metal type and thickness.

- Thin sheet metal (ducting, siding) → high TPI (14-24)

- Medium to thick metal (pipe, angle iron) → lower TPI (8-14), more aggressive teeth

- Hardened steel or cast iron → consider carbide tipped

Step 2: Choose the tooth technology.

- For general metal cutting: bi-metal blades suffice.

- For tougher metals (e.g., cast iron, alloy steel): go carbide tipped.

Step 3: Match to your saw and setup.

A reciprocating saw will reciprocate back and forth, so you’ll need a metal blade that can handle impact, vibration, and heat. Choose a blade with universal shank, proper length, and thickness.

Step 4: Select your blade from a reliable brand.

With so many options, brand matters. For example, EZARC provides a full collection for metal cutting: “Whether you need Sawzall blades for metal … choosing the right one makes all the difference.”

And if you’re looking for deeper help, check out our full guide:

👉 How to Select the Right Sawzall Blade – EZARC Tools Guide

A Top-Recommended Metal Sawzall Blade From EZARC

If you want a clear winner, check out this blade:

This is a premium metal cutting blade engineered for serious work. With an 8 TPI configuration and carbide-tipped teeth, it’s built to slice through thick metal, cast iron, and high alloy steel. If you’re doing heavy metal cutting with your Sawzall, then this is the blade for you.

For those browsing the full lineup of reciprocating saw blades, visit EZARC’s Reciprocating Saw Blades Collection.

Common Mistakes When Buying a Metal Sawzall Blade

- Buying a blade labelled for wood and assuming it’s fine for metal. It may work for very light metal but won’t last or perform.

- Ignoring TPI and tooth type. If the blade says 6 TPI and no mention of metal or carbide, it’s likely not optimized for metal.

- Choosing the cheapest blade. Cutting metal is tougher on blades. Spending a little more for engineered blades (like carbide tipped) often saves money over time due to fewer blade changes.

- Using the wrong length or thickness. Thin, flexible blades can twist or snap when cutting heavy metal.

- Neglecting proper saw speed or technique. The right blade helps, but your reciprocating saw must be used correctly (steady pressure, correct speed). Pairing the blade with the right tool matters.

Why EZARC Stands Out for Metal Blades

EZARC’s metal blade lineup stands out for several reasons:

- They provide clear TPI and material specs, making it easier to tell if a blade is for metal.

- They offer carbide tipped options (premium) and bi-metal options (cost efficient) for metal cutting.

- Their buying guide educates users (to choose right).

- Their collection is broad: from thin-metal 18 TPI blades to thick metal 8 TPI carbide blades.

This means, when you choose a metal Sawzall blade from EZARC, you’re getting a blade built for the job.

Final thoughts

If you’re wondering whether a blade is safe for metal or just another all-purpose one, look for:

- High enough TPI for the metal you’re cutting

- Labeling that includes “metal”, “metal cutting”, or “Sawzall blades for metal”

- Correct material (bi-metal, carbide)

- Specs that match the job (thickness, alloy)

Choosing a proper metal Sawzall blade will save you time, money, and frustration on the job. And when you’re ready for serious metal cutting with your reciprocating saw, EZARC’s premium blades make the difference.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。