Safety should always be the top priority when using reciprocating saws, these versatile and powerful tools can tackle a wide range of cutting tasks, but without proper precautions and handling, they can quickly become hazardous.

Understanding key safety tips not only protects you from injury but also helps you work more efficiently and confidently on every project.

If you’re the kind of person who likes to tackle your own renovations, builds, or yard work, these 9 safety tips are essential reading. And stick around until the end — we’ve got a blade recommendation that serious users are calling a game-changer.

Before you even touch the trigger, make sure you're wearing the right safety gear.

- 1. Always Inspect Your Tools And Gears For Safety Before Powering Up

- 2. Inspect Your Tool (And Blade) Before Every Use

- 3. Use the Right Blade for the Job

- 4. Secure Your Workpiece

- 5. Start Slow, Then Speed Up.

- 6. Mind the Kickback Zone

- 7. Use the Shoe!

- 8. Avoid Overhead Cuts (If You Can)

- 9. Unplug When Changing Blades

- Bonus: The Blade That’s Got Pros Talking

- Final Thoughts

1. Always Inspect Your Tools And Gears For Safety Before Powering Up

Before you press that power button, take a moment to inspect your tools and safety gear — it could save your fingers, your vision, or even your life. Take a look at the stats. This study noted that the higher injury rates among middle-aged users at home, along with changing gender roles, highlight the need for targeted safety measures and tailored prevention strategies for power tool use.

Power tools like reciprocating saws, grinders, and circular saws work under intense conditions. Over time, wear and tear is inevitable — cords fray, switches stick, guards loosen, and blades dull or crack. Ignoring these warning signs and diving straight into a project can lead to serious accidents, tool failure, or even fire hazards.

- Safety goggles or a full face shield to block flying debris.

- Cut-resistant gloves to protect your hands from sudden slips.

- Hearing protection, especially for long jobs.

- A dust mask or respirator when working with treated wood, insulation, or metal.

Tip: Don’t wear loose clothing or jewelry — the blade doesn’t care what it cuts.

2. Inspect Your Tool (And Blade) Before Every Use

Cracks in the housing, loose wiring, or dull blades can all turn your tool into a hazard. Do a quick inspection:

- Is the blade secure?

- Is the cord damaged?

- Does the tool wobble or spark when it starts?

Pro Tip: A lot of “kickback” issues happen due to dull blades. Use a blade designed for your specific task, and change it often. If you don't know what a kickback is, don't fret, just we will go through it below!.

3. Use the Right Blade for the Job

Reciprocating saws can cut wood, metal, PVC, and even concrete — but not with the same blade.

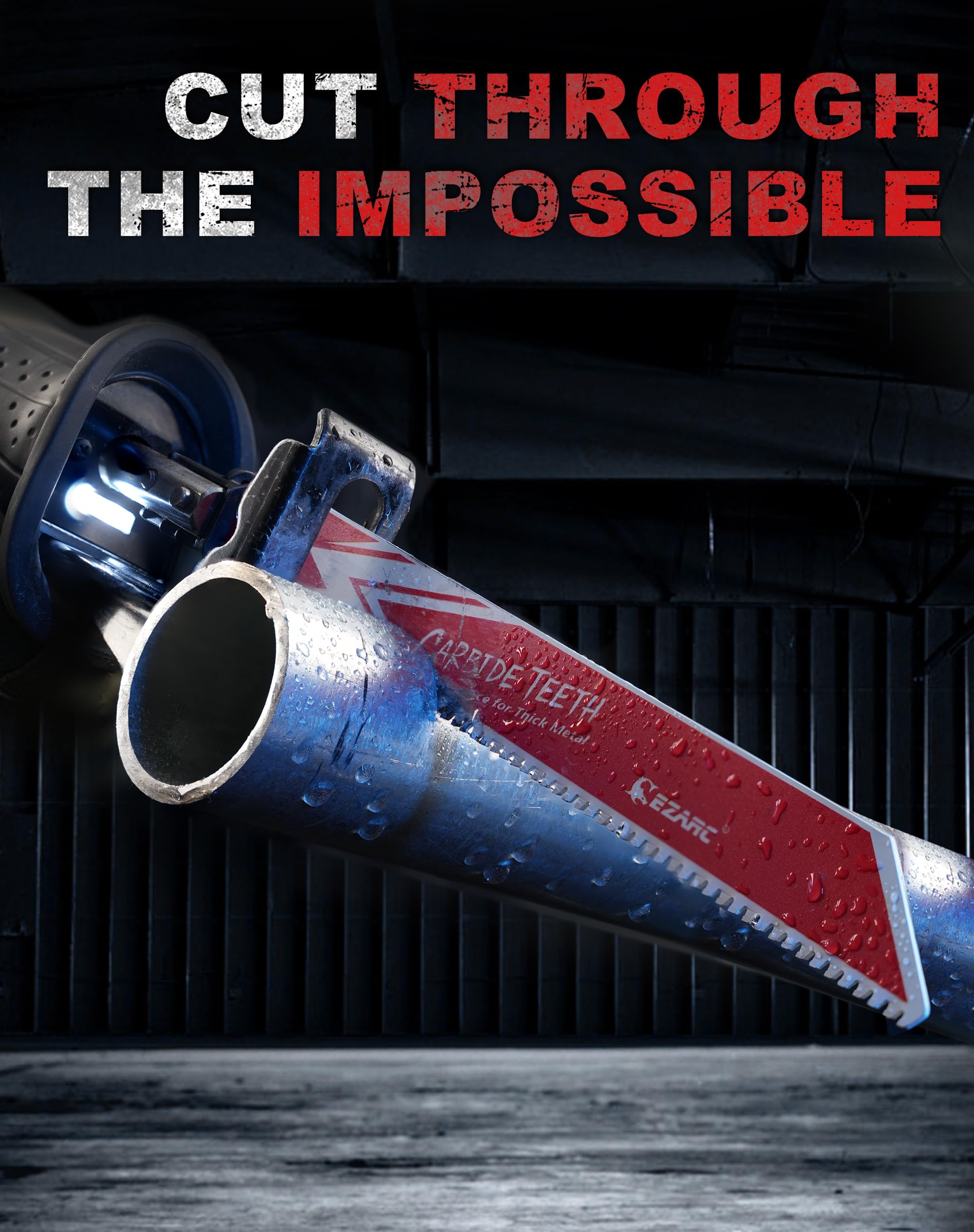

That’s why we recommend our Carbide-Tipped Reciprocating Blades, built to tear through hardened materials like rebar, treated wood, and nail-infested studs without slowing down. Compared to titanium blades, it offers up to 5x the lifespan and significantly less chattering.

👉 You may have seen these from many extremely well reviewed and rated blades on Amazon, Shopify and more. Pick one up from EZARC's website for exclusive deals!.

4. Secure Your Workpiece

If what you're cutting moves, you lose control. Clamp down materials whenever possible. Never try to "hold" a board with your foot or knee while cutting — that’s how hospital visits start.

As you can see below, the board is being clamped down while it can be cut smoothly and safely.

5. Start Slow, Then Speed Up.

Don’t jam the saw into the material. Let the blade make initial contact while running at low speed. Once it's biting, you can ramp it up.

When beginning a cut, especially on metal or slick surfaces, ease the blade into the material at a low speed. This helps the teeth bite cleanly and keeps the saw steady. Once the cut is established, you can gradually increase speed for faster progress without losing control.

This simple habit not only makes your cuts cleaner — it helps protect both you and your blade.

Why this matters: Starting fast increases the chance of blade skipping or binding, especially on slick surfaces like PVC or metal.

6. Mind the Kickback Zone

Kickback happens when the blade binds or hits an obstacle, causing the saw to jerk backward — often suddenly and forcefully. The most common trigger? The tip of the blade, especially during plunge cuts or when hidden nails or knots are involved.

Stay safe by:

- Letting the blade reach full speed before cutting

- Avoiding cuts with just the blade tip

- Keeping the shoe pressed firmly against the workpiece

- Watching for hidden nails or screws

- Holding the saw with both hands for better control

- AND USE THE SHOE!

Understanding and respecting the kickback zone helps you stay in control and avoid unexpected accidents.

7. Use the Shoe!

That flat metal plate near the blade (called the "shoe") isn’t just decoration. It stabilizes the saw and reduces vibration. Press it against the material as you cut to stay in control and extend blade life.

The shoe is designed to rest firmly against the workpiece, acting as a pivot point. This minimizes vibration, reduces kickback, and keeps the blade from bouncing or bending — which can happen easily if you’re cutting freehand. When you brace the shoe properly, it gives you a much more stable cut, allowing you to guide the saw with confidence and accuracy.

Above, Circled in Red, Is know as the "shoe" of a reciprocating saw. There are many ways to use the shoe,

Here’s how to use it effectively:

- Press the shoe firmly against the material before starting your cut. This gives you instant stability.

- Maintain pressure as you cut — this keeps the blade from grabbing or jumping unexpectedly.

- When cutting pipes or awkward shapes, pivot the saw on the shoe for better control.

- Adjust the shoe (if your model allows) to extend blade life by shifting the wear zone.

Ignoring the shoe often leads to rough, inaccurate cuts and increases the chance of losing control. So don’t treat it like an extra part — treat it like your third hand on the saw. Use it well, and you'll cut cleaner, safer, and smarter.

8. Avoid Overhead Cuts (If You Can)

Cutting above shoulder height reduces control and increases fatigue — two major risk factors for accidents. Use a ladder or reposition the material instead.

If you must cut overhead, use a lightweight saw and take extra breaks.

9. Unplug When Changing Blades

This one seems obvious — but in the middle of a long job, it’s easy to forget. Always unplug the saw (or remove the battery) before swapping out blades.

Also: Let the blade cool down first. Some metals can hit 300°F+ after a long cut.

Bonus: The Blade That’s Got Pros Talking

If you're tired of burning through cheap blades or struggling with cuts through tough nails or thick metal applications, meet our best-performing Carbide Teeth Reciprocating Saw Blade (SKU: 8021C13). Engineered for performance and built to last, it’s the ideal match for any serious reciprocating saw user.

And right now, we’re offering discounts, so grab one right now!.

👉 Click here to grab yours before it sells out

Final Thoughts

Reciprocating saws can be one of the most powerful tools in your workshop, but they demand respect. With the right precautions and gear, you’ll be free to cut, demo, and build safely for years to come. While you're

Got a project you're working on? Share your photos, tag us and comment below, we love seeing your work (and how our blades are making it easier).

Stay sharp, stay safe — and don’t forget, our 50% Summer Sale is on now! Visit our site to upgrade your gear and bring more performance to your work.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。