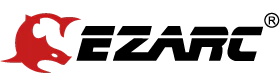

When it comes to demolition, few tools are as versatile and satisfying as a reciprocating saw with good reciprocating blades. From ripping through wooden beams to slicing metal pipes and concrete panels, this handheld powerhouse can take down nearly anything in its path—provided you’re using the right reciprocating blade for the job.

If you’ve ever burned out a blade mid-cut or struggled to get through a stubborn material, this guide is for you. Let’s explore how to choose and use the perfect different reciprocating blades for demolition projects, so you can demolish smarter, faster, and with more control.

Understanding Reciprocating Blades in Demolition Work

A reciprocating saw (often nicknamed a Sawzall) operates on a simple motion: back-and-forth strokes that chew through material with raw power. But the blade is what defines your cutting performance.

A demolition job rarely involves just one material—you’ll be tearing through wood, metal fasteners, drywall, PVC, and sometimes even concrete or brick. That’s why choosing a versatile, durable RSB (Reciprocating Saw Blades) lineup is essential.

At EZARC Tools, RSB blades are built specifically for these tough, mixed-material demolition environments—combining reinforced teeth, flexible backers, and high-performance alloys to withstand heavy-duty abuse.

What Makes a Blade “Demolition-Ready”?

Not all reciprocating blades is designed for demolition. A demolition blade is different because it prioritizes:

- Durability: Reinforced teeth and thicker bodies resist bending or snapping during aggressive cuts.

- Versatility: Capable of handling multiple materials—wood, nails, metal, and even masonry.

- Longevity: Advanced coatings and bi-metal or carbide-tipped designs extend blade life through rough conditions.

- Control: Wide, stiff designs reduce vibration, keeping cuts straighter and safer under pressure.

If your demolition projects involve mixed debris or unknown materials (like walls with embedded nails or pipes), an EZARC RSB Demolition Series blade is your best friend.

🛠️ Shop EZARC RSB Demolition Blades → [Buy Now!]

Choosing the Right Blade for Every Demolition Material

Let’s break down the best reciprocating blades by material type. Demolition often means all of the above—but knowing how each material behaves can save your blades and your patience.

1. Wood Demolition (with Nails, Screws, or Bolts)

When tearing out studs, frames, or flooring, you’ll often hit hidden nails and fasteners. Standard wood blades can dull instantly in this situation.

- Recommended Blade: Bi-metal demolition blade with 6–10 TPI (teeth per inch).

- Why: Low TPI blades chew through wood fast, while bi-metal teeth resist damage from nails.

- EZARC Tip: Use the EZARC RSB Wood & Nail Blade, built with precision-ground teeth and a reinforced body to power through both lumber and embedded metal.

Pro Tip: Keep a few extra blades handy. Demolition wood tends to trap dirt and debris, which dulls blades quickly.

2. Metal Demolition (Pipes, Rebar, Sheet, Angle Iron)

Cutting through metal is where quality really counts. Cheap blades will overheat, spark excessively, or wear out before finishing a single cut.

- Recommended Blade:10–14 TPI: For thicker metals (pipes, rebar, angle iron). 18–24 TPI: For thinner metals (sheet, ductwork, flashing).

- 10–14 TPI: For thicker metals (pipes, rebar, angle iron).

- 18–24 TPI: For thinner metals (sheet, ductwork, flashing).

- Why: Lower TPI cuts faster in thick stock; higher TPI provides control in thin materials.

-

Blade Type: Bi-metal or carbide-tipped blades are ideal for demolition-grade durability.

Pro Tip: Apply moderate pressure and let the blade do the work—forcing it increases heat and dulls the teeth faster.

3. Masonry and Concrete (Walls, Brick, Mortar)

Yes, you can use a reciprocating saw for light masonry demolition—with the right blade. While not a substitute for an angle grinder, it’s perfect for trimming or cutting through thin concrete, cement board, or mortar joints.

- Recommended Blade: Carbide-grit or carbide-tipped masonry blades with a reinforced body.

- Carbide-grit or carbide-tipped masonry blades with a reinforced body.

- Why: Regular steel or bi-metal blades will dull instantly against stone or concrete.

- EZARC Option: EZARC RSB Masonry Blade with carbide-grit edge for cutting through fiber cement, tile backer boards, and mortar lines with ease.

Pro Tip: Keep strokes slow and use minimal pressure. Dust buildup can reduce visibility—wear goggles and use a vacuum or blower if available.

🧱 View EZARC's Solution Engineered Specifically For Concrete

4. Multi-Material Demolition (Walls, Roofs, Flooring)

In real-world demolition, you’ll often encounter mixed materials—wood with nails, drywall backed by metal studs, or roofing with tar and shingles.

That’s where variable TPI blades come in.

- Recommended Blade: Variable 10–18 TPI multi-material blade.

- Variable 10–18 TPI multi-material blade.

- Why: Offers flexibility—coarse sections handle wood, fine sections tackle metal without swapping blades.

- EZARC Blade: RSB Multi-Material Demolition Blade, featuring a tapered profile and aggressive variable tooth pitch for all-purpose demolition.

Pro Tip: These are ideal for contractors, remodelers, or anyone who wants a “one-blade-fits-all” solution during chaotic tear-downs.

How to Use Reciprocating Blades Safely and Efficiently in Demolition

Even the best reciprocating blade needs the right technique. Follow these best practices for smoother cuts, longer blade life, and fewer tool hiccups.

- Secure the Material: Clamp or stabilize the workpiece whenever possible. Vibrations shorten blade life.

- Use Correct Speed Settings: For hard materials like metal, use slower speeds; for wood or debris, go faster.

- Avoid Binding: Let the saw’s weight and motion handle the cutting—forcing it causes bending and wear.

- Lubricate When Needed: A drop of cutting oil on metal cuts helps reduce friction and heat.

- Watch Blade Heat: If the blade starts smoking or turning blue, it’s overheating—pause to cool it down.

- Inspect Regularly: Dull or damaged teeth increase vibration, risk kickback, and slow progress.

💡 Pro Insight: EZARC RSB blades feature anti-vibration designs and optimized tooth geometry, keeping you in control even through unpredictable demolition tasks.

When to Replace Your Reciprocating Blades

Even premium blades have limits. The key to the perfect cutting session and experience is knowing when to replace your reciprocating blade:

- Cuts feel slower or rougher than usual.

- Teeth appear rounded or chipped.

- Sparks increase, or the blade discolors.

- The saw vibrates excessively.

Continuing to use a worn blade increases effort and risk—fresh blades are cheaper than wasted time or damaged tools.

Why Choose EZARC RSB Blades for Demolition

EZARC’s RSB Blade Series is designed from the ground up for professionals who demand toughness and versatility. Here’s what sets them apart:

- Bi-Metal & Carbide Construction: For superior heat resistance and flexibility.

- Thick, Reinforced Bodies: Prevent bending and ensure straight cuts under stress.

- Optimized Tooth Geometry: Cuts faster while lasting longer.

- Wide Range of Options: From wood and metal to masonry and multi-material use.

- Engineered for Longevity: Up to 10x longer lifespan in demolition conditions.

🧩 Discover EZARC’s Complete RSB Blade Range → [Shop All Reciprocating Blades ]

Common Questions About Demolition Blades

Can I use one reciprocating blade for everything?

Variable-TPI multi-material blades are designed for that, but specialized blades perform best on specific materials.

What’s the best reciprocating blade for metal studs in drywall?

Use an 18–24 TPI bi-metal or carbide blade. It’ll slice through both drywall and thin steel without snagging.

Can reciprocating blades cut concrete? Yes, but only with carbide-grit or carbide-tipped blades meant for masonry.

How do I make my demolition blades last longer?

Avoid forcing cuts, keep materials supported, and swap blades before they’re completely dull.

Final Thoughts

Demolition is messy—but your cuts don’t have to be. The right reciprocating blade turns chaos into control, slicing through anything in your way with confidence.

Whether you’re stripping down a wall, removing pipes, or cutting through nailed lumber, EZARC’s RSB Demolition Blades deliver the durability, speed, and versatility you need to finish strong.

Don’t let a weak blade slow you down—upgrade your arsenal and tear through demolition like a pro.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

Dejar un comentario

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.