Cutting through thick metal with a reciprocating saw can feel like a battle—one you don't want to lose because of a bad blade. The right sawzall blades make all the difference, whether you're tackling automotive jobs, demolition, or a mild “DIY-metal-mageddon.” Let’s dig into how you can slice through heavy metal with confidence, avoid common pitfalls, and pick blades that last.

Why Sawzall Blades Matter for Metal Cutting

If you've ever tried slicing a stubborn steel pipe or sheet with the wrong blade, you know frustration. Standard blades might work for wood, but thick metal is a different beast; you need metal reciprocating saw blades that deliver clean, efficient cuts without burning out or snapping.

Sawzall blades for metal aren’t just sharpened strips of steel—they're engineered for durability, speed, and control. The right blade minimizes downtime, maximizes safety, and spares you from hand cramps worthy of a weightlifter.

Key Types of Sawzall Blades for Metal

Before heading to the checkout, know your options. Choosing between metal cutting reciprocating saw blades involves more than “which is shinier." Let’s break down the main types:

- Bi-Metal Sawzall Blades: A favorite for pros and weekend warriors alike. They combine high-speed steel teeth with a flexible spring steel back, offering longevity and resilience. Excellent for most metal tasks, they resist shattering and withstand heat better than plain carbon blades.

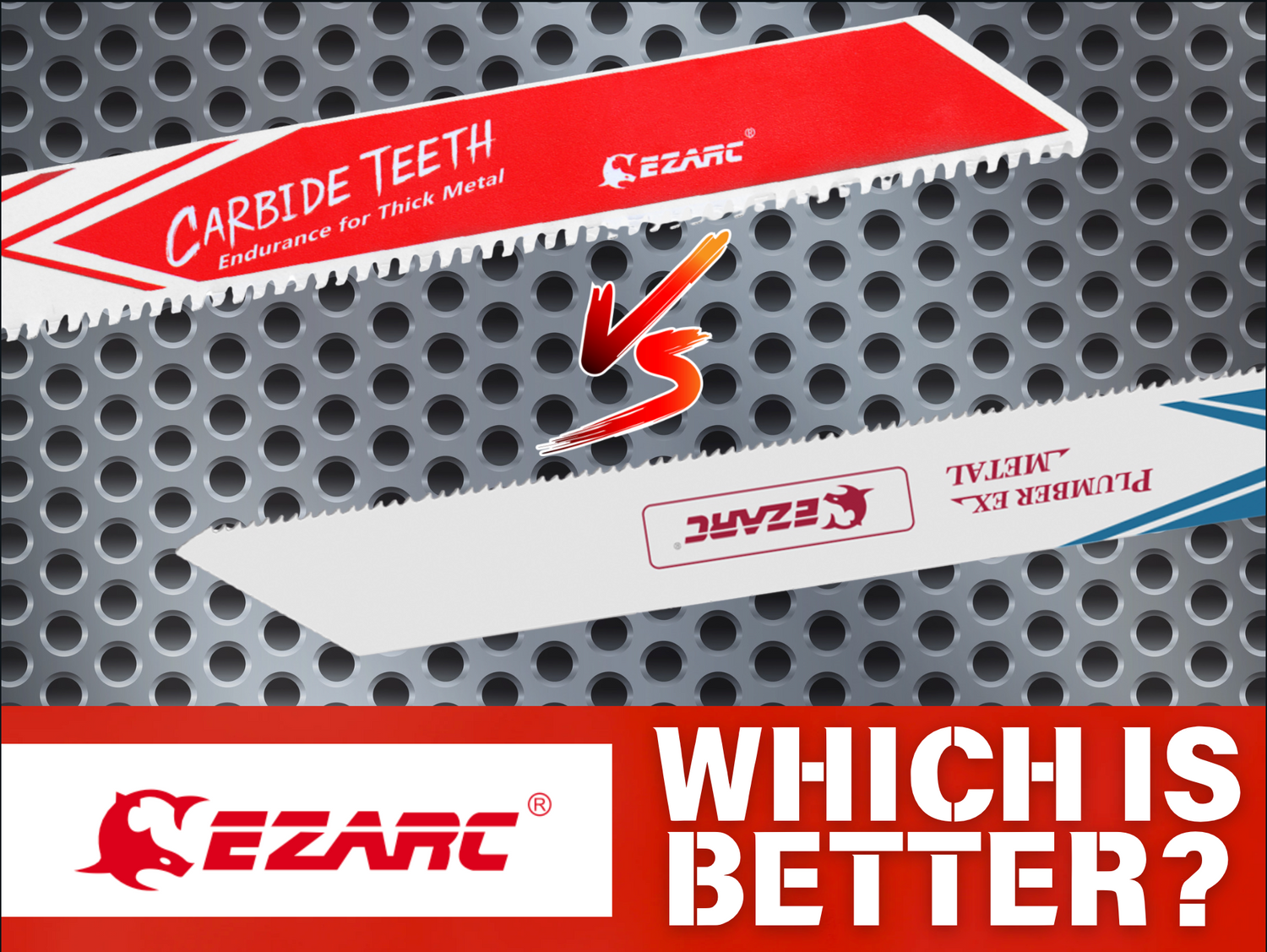

- Carbide Sawzall Blades: A true titan for thick, tough metals. The cutting edge is tipped or coated with carbide—an industrial-grade material harder than almost anything you’re likely to encounter on the job site. Carbide sawzall blades chew through stainless steel, cast iron, and thick gauge steel like a hot knife through butter (just don’t spread it on toast).

- Specialty Metal Cutting Reciprocating Saw Blades: Some blades are made specifically for a tricky job—think demolition work involving nails or a mix of materials. Look for features like variable tooth pitch and reinforced teeth if you need a blade for the long haul.

What Makes the Best Sawzall Blades for Metal?

If you want to get real value (and avoid the embarrassment of a wimpy blade halfway through your cut), focus on these criteria:

- Material & Construction: Quality bi-metal or carbide construction is non-negotiable. Bi-metal sawzall blades offer a well-balanced mix of flexibility and edge retention, while carbide blades tip the scale towards extreme durability.

- Tooth Design & TPI (Teeth Per Inch): When it comes to thick metal, more teeth are not always better. A lower TPI (8-14) is ideal, offering each tooth more bite and less clogging. Higher TPI blades are better for thinner sheets.

- Blade Thickness & Length: Thicker blades resist bending and vibration—crucial when you’re cutting chunky materials. Longer blades allow deeper cuts, but if your sawzall is as old as your favorite band t-shirt, check its stroke length first!

- Brand Reliability: Not all blades are created equal. Look for brands that focus on innovation, robust design, and real-world performance—such as Ezarc Tools, who have been earning pros’ trust for their durable and high-performing metal cutting reciprocating saw blades.

When Should You Choose Carbide Sawzall Blades?

Here’s a little secret: carbide reciprocating saw blades can seem overkill for basic projects, but if you’re working on projects involving thick pipes, rebar, structural steel, or heavy-duty demolition, they’re a game-changer. Carbide not only stays sharp longer, but it also shrugs off the heat and abuse that would dull or snap ordinary blades.

Here’s a little secret:

carbide sawzall blades can seem overkill for basic projects, but if you’re working on projects involving thick pipes, rebar, structural steel, or heavy-duty demolition, they’re a game-changer. Carbide not only stays sharp longer, but it also shrugs off the heat and abuse that would dull or snap ordinary blades. \n \n \n \n \n \n \n \n \n \n \n \n \n ","contentAlignProduct":"Center","infoProduct":{"id":"gid://shopify/Product/6981334040727","title":"Thick Metal/Cast Iron Cutting – Carbide, 6/9 in, 8 TPI Reciprocating Saw Blade","currencyCode":"USD","amountMax":"104.97","amountMin":"16.95","price":"69.97","compareAtPrice":null,"imagesUrl":"https://cdn.shopify.com/s/files/1/0575/4975/0423/files/9in.jpg?v=1735278307&width=600","urlStore":"/products/8tpi-6-9-in-carbide-reciprocating-saw-blade-for-thick-metal-cast-iron-alloy-steel","altImage":"8TPI, 6/9 in. Carbide Reciprocating Saw Blade For Thick Metal/Cast Iron/Alloy Steel - EZARC Tools"},"colorTitle":{"hue":213,"brightness":0.83,"saturation":1},"colorPrice":{"hue":0,"saturation":1,"brightness":0},"colorDiscount":{"hue":356,"saturation":0.74,"brightness":1},"isRemoveBranding":true,"hidden":false,"locked":false,"blockName":"Text and product","componentId":"undefined"}

Here’s a little secret:

carbide sawzall blades can seem overkill for basic projects, but if you’re working on projects involving thick pipes, rebar, structural steel, or heavy-duty demolition, they’re a game-changer. Carbide not only stays sharp longer, but it also shrugs off the heat and abuse that would dull or snap ordinary blades.

Bi-metal sawzall blades are a trusty all-rounder, especially for repetitive medium-gauge work. But for steel that’s measured in “inches” rather than “millimeters,” carbide-tipped blades keep your saw from sounding like it swallowed a sack of marbles.\n \n \n \n \n \n \n \n \n \n \n \n \n ","contentAlignProduct":"Center","infoProduct":{"id":"gid://shopify/Product/6981334204567","title":"Heavy Metal Cutting – Bi-Metal, 6/9/12 in, 14 TPI Reciprocating Saw Blade","currencyCode":"USD","amountMax":"84.95","amountMin":"13.95","price":"49.97","compareAtPrice":"69.97","imagesUrl":"https://cdn.shopify.com/s/files/1/0575/4975/0423/files/6._80201625.jpg?v=1735551032&width=600","urlStore":"/products/heavy-metal-cutting-bi-metal-sawzall-blades-14tpi","altImage":"14TPI,6/9/12 in. Bi-Metal Reciprocating Saw Blade For Heavy Metal Cutting - EZARC Tools"},"colorTitle":{"hue":213,"brightness":0.83,"saturation":1},"colorPrice":{"hue":0,"saturation":1,"brightness":0},"colorDiscount":{"hue":356,"saturation":0.74,"brightness":1},"isRemoveBranding":true,"hidden":false,"locked":false,"blockName":"Text and product","componentId":"undefined"}

Bi-metal sawzall blades are a trusty all-rounder, especially for repetitive medium-gauge work. But for steel that’s measured in “inches” rather than “millimeters,” carbide-tipped blades keep your saw from sounding like it swallowed a sack of marbles.

Bi-metal reciprocating saw blades are a trusty all-rounder, especially for repetitive medium-gauge work. But for steel that’s measured in “inches” rather than “millimeters,” carbide-tipped blades keep your saw from sounding like it swallowed a sack of marbles.

How to Maximize Blade Life and Efficiency

Nothing ruins momentum like a blade burning out halfway through a job. To get the most from your saw blades for metal, keep these tips in mind:

- Let the Blade Do the Work: Pressing too hard wears out the teeth and creates unnecessary heat. Modern blades, especially carbide and bi-metal, cut better when guided with steady pressure.

- Use the Right Speed: Many reciprocating saws feature variable speed. Thick metal needs a slower speed—think “cruise, don’t race.” This prevents overheating and preserves blade life.

- Lubrication is Your Friend: Don’t let friction become a foe. For heavy cuts, a squirt of cutting oil cools the blade and flushes away debris. Your blade (and your patience) will thank you.

- Switch When Needed: If you notice more sparks than a 4th of July parade, or the cut feels sluggish, retire the blade. A fresh blade is safer and far more effective.

Ezarc Tools: Raising the Bar for Metal Cutting

Talking about the best reciprocating saw blades for metal wouldn’t be complete without highlighting Ezarc Tools. With a focus on real-world needs rather than flashy gimmicks, Ezarc produces metal reciprocating saw blades that combine advanced materials with ergonomic design.

Why consider Ezarc for your next project?

- Premium Materials: Ezarc uses both bi-metal and carbide technologies, optimizing for longevity, precision, and speed across a variety of applications.

- Specialization in Metal: Their reciprocating saw blades metal range covers everything from demolition to fine fabrication—ensuring you always have the right tool for thick or thin metals.

- Customer-Centric Innovations: Features like anti-stick coatings and variable pitch teeth provide smoother cuts and reduce frustrating blade jams.

- Durability Tests: Ezarc blades are tested on real thick-stock metal, so you can expect them to triumph where basic blades falter.

Real-World Applications: Sawzall Blades for Metal in Action

Whether you’re a contractor, auto enthusiast, plumber, or impromptu metal artist (it happens!), the right reciprocating saw blades for metal make all the difference.

- Automotive Repairs: Cutting exhaust pipes or removing stubborn bolts is a breeze with carbide blades—no magic wand required.

- Demolition & Renovation: When tearing down old metal framing or pipes, bi-metal blades handle hidden nails without skipping a beat.

- Home Improvement: Even routine home repair jobs, like trimming metal siding or slicing steel conduit, become simpler with blades suited specifically for metals.

Remember, nobody ever won a medal for struggling with the wrong blade!

How to Choose the Perfect Metal Cutting Reciprocating Saw Blades

The jungle of options in the tool aisle can be overwhelming. Here’s a quick decision guide:

- Thickness of Material: For metals thicker than 1/8", stick with carbide reciprocating saw blades. For lighter-gauge metals, bi-metal options are often sufficient and more cost-effective.

- Expected Abuse Level: If you’ll be hitting nails, screws, or layered materials, look for variable tooth pitch and reinforced backs.

- Saw Compatibility: Double-check that your reciprocating saw is compatible with standard-sized blades. (Pro tip: a little dance with the instruction manual now saves frustration later.)

- Your Comfort: Look for features that minimize vibration and offer quick, precise starts—because nobody likes chasing a wandering blade.

Caring for Your Sawzall Blades

Treat your blades right and they’ll serve you loyally through thick and thin (metal). Here’s how:

- Storage Matters: Store in a dry, organized case. Moisture leads to rust, which nobody wants, unless you’re into the “patina” look.

- Regular Inspection: After each use, check teeth for chips or rounding. Early replacement prevents unwelcome surprises mid-cut.

- Proper Cleaning: Remove debris and metal shavings after use. A quick brush-off keeps the blade sharp and safer for future cuts.

Choosing the best reciprocating saw blades for cutting thick metal isn’t rocket science, but it does pay to know your options. With bi-metal and carbide options from innovators like Ezarc Tools, cutting stubborn metal just got easier—and a fair bit more fun. Ready to up your metal-cutting game? The right blade is out there, waiting to slice through your toughest projects.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

Dejar un comentario

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.