When you hear "reciprocating saw" (or Sawzall), you probably picture it cutting wood, pipes, or even trimming tree branches. But here’s the big question: can you get a blade tough enough to cut concrete with one?

The answer: Yes, you can. But before grabbing the first blade you see, let’s explore what makes a concrete reciprocating saw blade different, when to use one, and why a masonry Sawzall blade is a must for demolition jobs.

- 1. Why You Can’t Use Standard Blades on Concrete

- 2. What Is a Concrete Sawzall Blade?

- 3. When to Use a Sawzall Blade for Concrete

- 4. The Best Option: EZARC Brick & Concrete Cutting Sawzall Blades

- 5. Advantages of Using a Concrete Sawzall Blade

- 6. How to Pick the Right Blade for Your Project

- 7. Tips for Getting the Most Out of Your Concrete Blade

- 8. Final Thoughts

Why You Can’t Use Standard Blades on Concrete

Concrete isn’t like wood or steel—it’s abrasive, gritty, and full of aggregate that destroys normal blades. A wood blade will burn out instantly, and a metal blade might only survive a cut or two before going dull.

That’s why you need a blade designed for the job. Concrete reciprocating saw blades are engineered with carbide or diamond tips and a low TPI (teeth per inch) so they can grind through brick, block, and porous concrete without failing.

What Is a Concrete Sawzall Blade?

A concrete reciprocating saw blade—also called a masonry Sawzall blade—is built for heavy demolition. Unlike fine-tooth blades for metal or aggressive-tooth wood blades, masonry blades are:

- Carbide-Tipped or Diamond-Grit: Reinforced to survive abrasive materials.

- Wide & Thick: Prevents wobbling and keeps cuts straight.

- Low TPI (around 2): Quickly clears out dust and grit.

- Extra-Long (12” & 18”): For deep cuts in masonry walls or when working in tight spaces.

When to Use a Sawzall Blade for Concrete

A Sawzall won’t replace a full-sized demolition saw, but it’s unbeatable in tight, controlled demolition jobs. Ideal scenarios include:

- Bathroom Remodels: Removing brick or old concrete backer board.

- Basement Work: Cutting cinder blocks for window or door openings.

- Tight Spaces: Places where large concrete saws won’t fit.

- Foundation Renovations: Cutting through porous or aerated concrete.

Need help choosing? Check out our Sawzall blade guide.

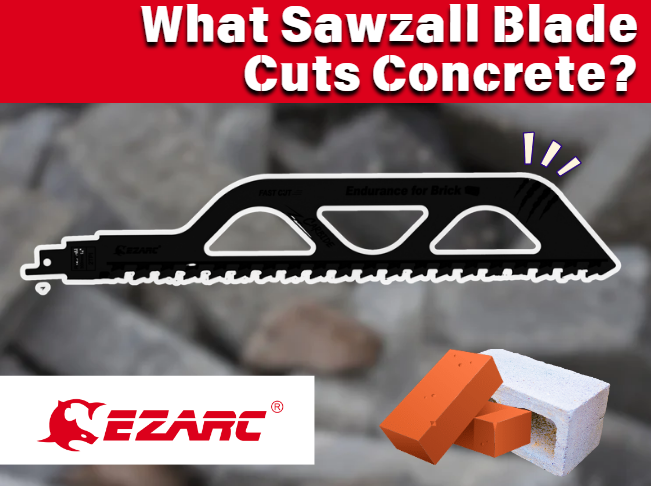

The Best Option: EZARC Brick & Concrete Cutting Sawzall Blades

Not all concrete blades are equal. For professional results, the EZARC Brick & Concrete Cutting – Carbide Sawzall Blade stands out.

Why Pros Choose EZARC:

- Carbide-Tipped Tungsten Teeth: Cuts brick, porous concrete, cinder blocks, and aerated concrete with 2X the life of standard masonry blades.

- 12” & 18” Options:12” for tight spaces & plunge cuts (up to 225mm).18” for deep cuts in walls & columns (up to 370mm).

- 12” for tight spaces & plunge cuts (up to 225mm).

- 18” for deep cuts in walls & columns (up to 370mm).

- Durable Build: 1.5mm-thick steel backbone resists bending, while the wide 50mm body keeps cuts steady.

- Cleaner Results: Up to 40% less dust and neater edges compared to conventional masonry blades.

- Universal Fit: Works with all major Sawzall brands.

Advantages of Using a Concrete Sawzall Blade

Here’s why choosing a proper concrete reciprocating saw blade pays off:

- Saves Time: Faster cutting through masonry.

- Saves Money: Longer blade life means fewer replacements.

- Cleaner Results: Less chipping and less dust.

- Versatile: Handles brick, block, and aerated concrete.

- Portable: Easy to maneuver without hauling heavy equipment.

How to Pick the Right Blade for Your Project

Not sure which blade to choose? Here’s a quick guide:

- 12-inch blades: Best for compact areas and plunge cuts.

- 18-inch blades: Perfect for thicker walls and deep demolition cuts.

- Always go carbide-tipped for abrasive masonry jobs.

Read Our Full EZARC Blade Selection Guide.

Tips for Getting the Most Out of Your Concrete Blade

Owning a high-quality concrete blade is only half the battle—knowing how to use it effectively makes a huge difference in performance, safety, and longevity. Here are some tips to help you maximize your masonry Sawzall blade:

- Use the Right Speed: Reciprocating saws often have variable speed. When cutting concrete, use a slower, controlled speed to prevent overheating and premature wear on the concrete blade.

- Secure Your Workpiece: Always clamp down bricks, blocks, or concrete panels before cutting. This stabilizes the material, reduces vibration, and ensures your concrete blade cuts straight and smooth.

- Let the Blade Do the Work: Don’t force the saw. Pressing too hard can damage the blade and your saw. A carbide-tipped concrete blade is designed to grind through masonry with minimal pressure.

- Keep It Cool: Cutting masonry generates heat. Pause periodically for long cuts to prevent the blade from overheating, which can shorten its lifespan.

- Wear Proper Safety Gear: Always wear eye protection, gloves, and a dust mask. Even with a high-quality concrete blade, cutting brick or aerated concrete produces dust and small debris.

- Inspect and Replace When Needed: A worn concrete blade will produce slower, rougher cuts. Check your blade regularly and replace it to maintain clean, efficient cutting.

By following these simple practices, your concrete blade will deliver better performance, last longer, and make even challenging demolition jobs more manageable.

Final Thoughts

So, can you get a concrete blade for a reciprocating saw? Absolutely. With the right masonry Sawzall blade, your reciprocating saw becomes a demolition powerhouse for brick, block, and porous concrete.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

Metal Worker & Fabrication

Metal Worker & Fabrication

Woodworking & Carpentry

Woodworking & Carpentry

Electrical & Plumbing

Electrical & Plumbing

Automotive

Automotive

Concrete & Masonry

Concrete & Masonry

Demolition

Demolition

NEW ARRIVALS

NEW ARRIVALS

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.